Activated Sludge

Advanced Activated Sludge Systems for Reliable Wastewater Treatment for Industry

Hydroflux provides advanced Activated Sludge Systems engineered for efficient and reliable wastewater treatment across a wide range of industries.

The Activated Sludge process is one of several aerobic technologies we specialise in, and we will always explore alternative options to determine the most effective solution for each unique case. Our goal is to ensure optimal treatment efficiency and deliver long-term benefits.

Some of the main benefits of the activated sludge process are:

- Aeration can be conducted in above-ground tanks or ponds using a variety of aeration methods

- The separation of biomass occurs in a conventional clarifier or DAF system

- Activated sludge plants can be easily configured for high efficiency Biological Nutrient Removal (BNR) by incorporation of anoxic zones or tanks upstream of the main reactor

- Chemical phosphorous removal can be incorporated into the clarification process

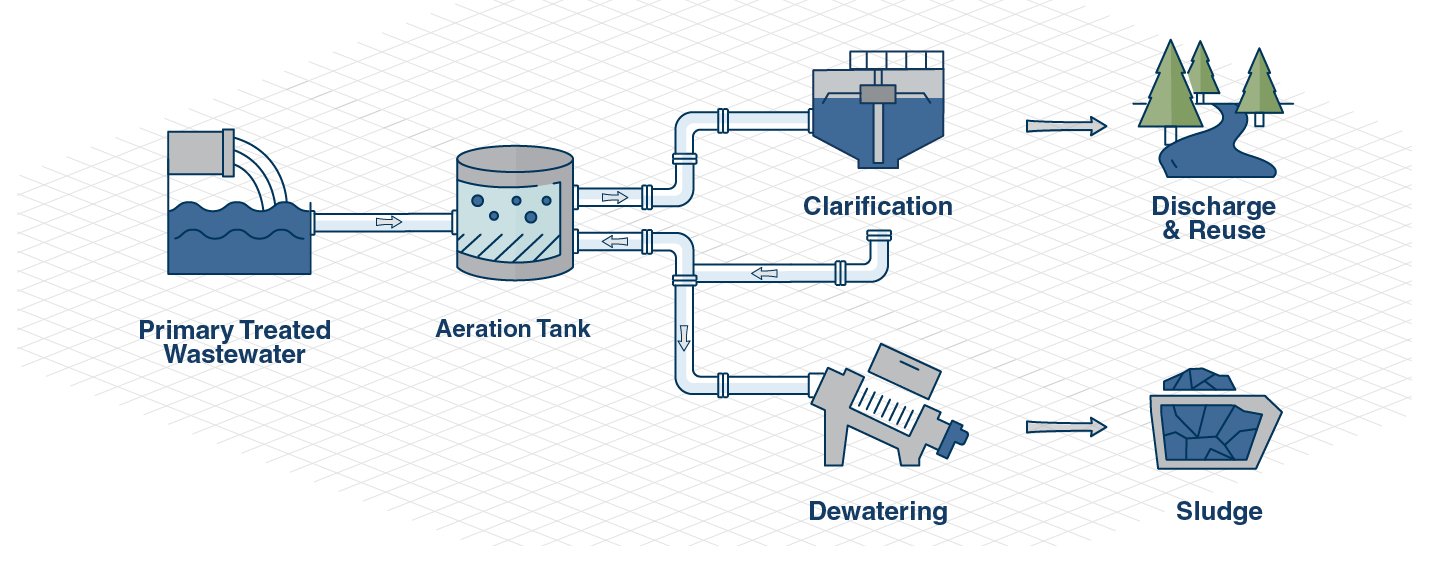

How the Activated Sludge Process Works

The activated sludge process is a conventional aerobic wastewater treatment system that includes an aeration zone, followed by biomass clarification and waste-activated sludge dewatering. Biomass clarification can be achieved using either a clarifier or a HyDAF system. In industrial applications, Dissolved Air Flotation (DAF) systems are increasingly favoured for use alongside activated sludge systems due to their compact footprint and enhanced separation efficiency.

The Stages of the Activated Sludge Process

1. Wastewater is introduced into the aeration tank at a constant flow rate where oxygen is introduced and biologically treated wastewater flows out of the aeration tank directly into a clarifier or HyDAF system.

2. The clarifier or HyDAF system removes the biomass in the wastewater, and the treated water flows to the point of discharge.

3. The removed biomass is dewatered, further processed / dewatered, and usually removed from the site as waste-activated sludge (WAS). Some biomass is returned to the aeration tank as mixed liquor return (MLR) to retain sufficient biomass for the treatment process.

4. If additional Nitrogen removal is required, an anoxic tank is often incorporated upstream of the aeration tank where nitrification and denitrification occur.

Nutrient removal

Nitrogen removal can be incorporated into the activated sludge process by the inclusion of an anoxic zone upstream of the aeration tank with a mixed liquor return (MLR) loop that recirculates water between the aeration and anoxic tanks. Some phosphorous will be taken up in the biological process however, if very low concentrations are required, a simple addition of coagulant at the clarification plant inlet will precipitate phosphorous from the clarified water stream.

Highly Efficient Aeration

Activated sludge plants can be designed using a variety of configurations, including above ground tanks or ponds, to accommodate different types of wastewater treatment needs. These systems utilise various aeration methods to provide the necessary oxygen for the microbial community to break down organic pollutants. Common aeration methods include fine bubble diffusers, surface aerators, and submersible aerators. Each method has its advantages depending on the plant’s design and operational requirements.

Surface aerators are often used for large, shallow basins, while submersible aerators are often the ideal choice for smaller applications. Fine bubble diffusers, on the other hand, distribute air more efficiently, creating smaller bubbles that provide greater oxygen transfer, which is crucial for optimising the treatment process.

At Hydroflux, we prefer to use Aerostrip fine bubble diffusers where possible, as they offer the most sustainable solution in terms of energy efficiency. These diffusers have been proven to deliver high oxygen transfer rates with lower power consumption compared to other aeration technologies. The choice of aeration method, however, depends on several factors, including the configuration of the aeration basin, the depth of the tank, and the specific oxygen demands of the wastewater being treated. By carefully evaluating these factors, we ensure that the most suitable and efficient aeration system is selected for each project, optimising both performance and energy usage for long-term sustainability.

Selecting the Optimum Means of Clarification for your Activated Sludge Plant

The primary function of a clarifier in wastewater treatment is to separate the biomass, or activated sludge, from the treated wastewater stream. This has been traditionally achieved through settling, where the biomass naturally sinks to the bottom of the clarifier tank. Once the biomass settles, it forms a sludge layer at the base of the clarifier, which is then withdrawn and usually dewatered, with some returned to the aeration process as return activated sludge (RAS).

Dissolved Air Flotation (DAF) using the HyDAF is an excellent alternative to clarifiers in industrial wastewater applications, offering several distinct advantages.

DAF systems operate with a surface loading rate that is at least five times greater than clarifiers, significantly reducing the required footprint and allowing for more compact system designs. The sludge generated by a DAF system typically contains a much higher percentage of dry solids, which results in lower volumes of waste-activated sludge that need to be further processed, making it more efficient and cost-effective in the long term. Additionally, because the DAF system removes biomass via flotation, it is capable of handling scum and buoyant biomass that can form during upsets in the biological treatment process. This ensures that even under fluctuating conditions, the system continues to effectively remove undesirable solids from the aeration process.

Activated Sludge FAQs

Activated sludge systems commonly face issues like bulking sludge, where poor settling in the clarifier—often due to filamentous bacteria—leads to high suspended solids and reduced treatment efficiency. This can be managed by optimising the food-to-microorganism ratio, adjusting aeration, and using selector tanks to encourage floc-forming bacteria. Foaming is another problem, typically caused by Nocardia and Microthrix in high FOG conditions. Pre-treatment with DAF systems, maintaining appropriate sludge age, and optimising aeration can reduce foaming, while water sprays or antifoam agents offer short-term relief.

Other challenges include low dissolved oxygen (DO) levels, which impair biological activity and can cause odours if anaerobic conditions develop. Regular monitoring, adjusting aeration, and maintaining diffusers help maintain adequate DO levels. Toxic shock events from industrial discharges or pH spikes can also disrupt microbial communities and affect performance. These risks can be reduced through industrial pre-treatment, careful chemical management, and use of buffer tanks to smooth out influent variability.

A secondary clarifier is the traditional and somewhat conventional choice for separating biomass in an activated sludge system, relying on gravity to settle flocculated microorganisms. The settled sludge is either returned to the aeration tank as Return Activated Sludge (RAS) to maintain microbial populations or removed as Waste Activated Sludge (WAS) for further processing. Clarifiers are energy-efficient and work well when sludge has good settling characteristics. However, they can struggle with bulking sludge caused by filamentous bacteria, leading to poor separation and high effluent solids.

A Dissolved Air Flotation (DAF) system, on the other hand, uses fine air bubbles to float the biomass to the surface rather than relying on settling. DAF is particularly effective for poorly settling sludge, such as filamentous or light flocs that would otherwise cause clarifier issues. It also produces a more concentrated sludge, reducing sludge handling costs. However, DAF units require more energy due to air compression and may involve higher operational costs. If the plant experiences bulking sludge, poor settling, or needs a higher degree of solids removal, DAF may be the better choice. Conversely, if the sludge settles well and energy efficiency is a priority, a clarifier remains the preferred option.

The amount of Waste Activated Sludge (WAS) generated in an activated sludge system depends on factors such as influent organic load (BOD/COD), sludge retention time (SRT), and system efficiency. On average, activated sludge systems produce 0.3–0.5 kg of dry sludge per kg of BOD removed. For example, a system treating 1,000 kL/day of wastewater with an influent BOD of 1,000 mg/L could generate 300–500 kg of dry sludge per day. Since WAS typically has a solids concentration of 0.5–1.5% (5,000–15,000 mg/L TSS) before thickening, this translates to a liquid WAS volume of approximately 40–80 kL/day before dewatering.

If a Dissolved Air Flotation (DAF) system is used for sludge thickening, it can increase the solids concentration to around 3% (30,000 mg/L TSS), significantly reducing the sludge volume. This means that instead of 40–80 kL/day of liquid WAS, the thickened sludge volume could be reduced to approximately 10–20 kL/day. Whilst the amount of dewatered solids remains the same, the cost, capacity, and operating time of the dewatering plant when using a DAF can be reduced.

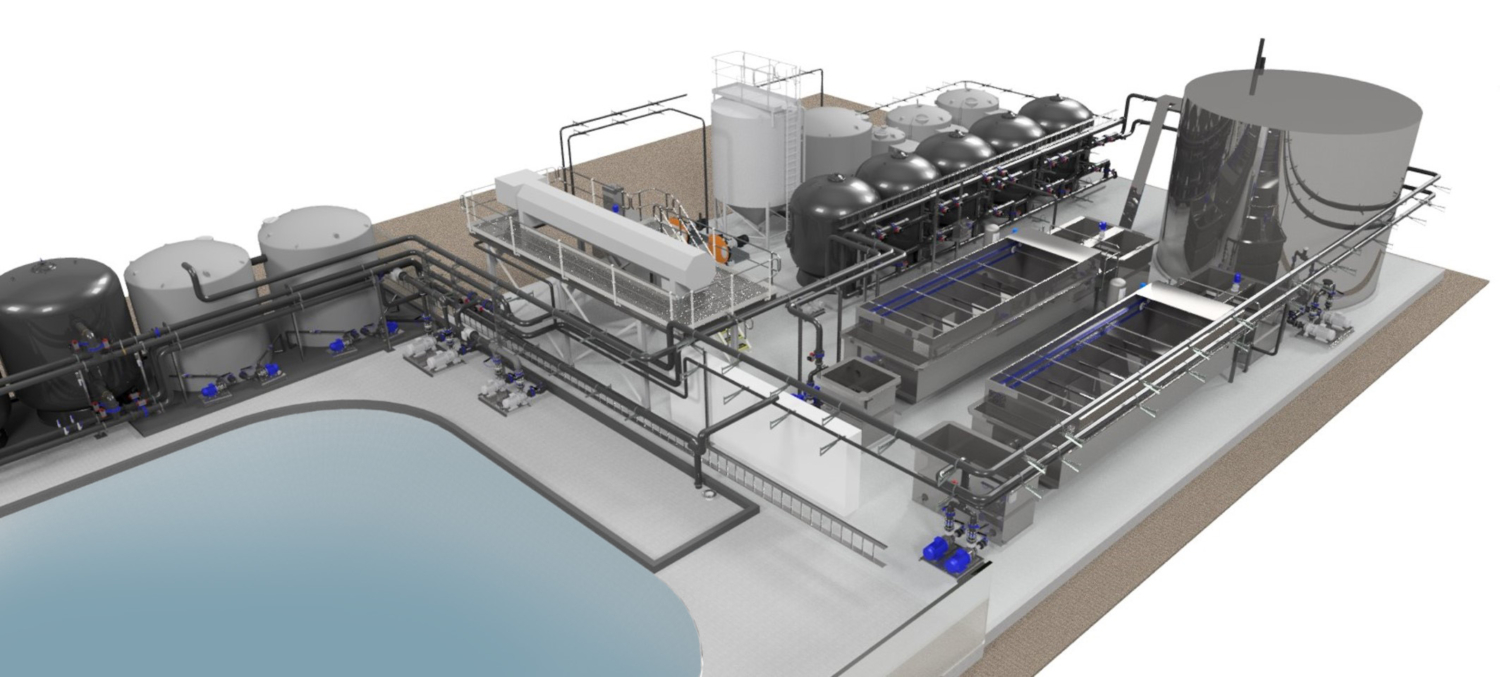

Design and Construction Capabilities

Hydroflux can deliver complete design and construct projects that cover all stages of treatment, including primary, secondary biological, sludge handling and tertiary processes. Our systems are designed to enable high-quality discharge or water reuse, with flexible delivery models available from equipment supply to integration of full turnkey solutions.

Our team comprises qualified civil, mechanical, chemical, and electrical engineers, along with experienced project managers, site supervisors, commissioning specialists, and service technicians. With offices located throughout Australia, we are able to provide local support from concept through to installation. To maintain long-term performance and reliability, Hydroflux also offers comprehensive servicing and maintenance contracts.

Contact us for a technical discussion about how we can assist you with your wastewater treatment facility.

Sustainable Solutions

As Australia’s first certified carbon-neutral water and wastewater chemical supply and service business, we focus on sustainability. Developing and delivering sustainable solutions for treatment plant operation and maintenance is at the core of what we do. Our equipment is the most sustainable in the Australian and New Zealand markets and is also carbon-neutral. Click here to find out what this means for you.